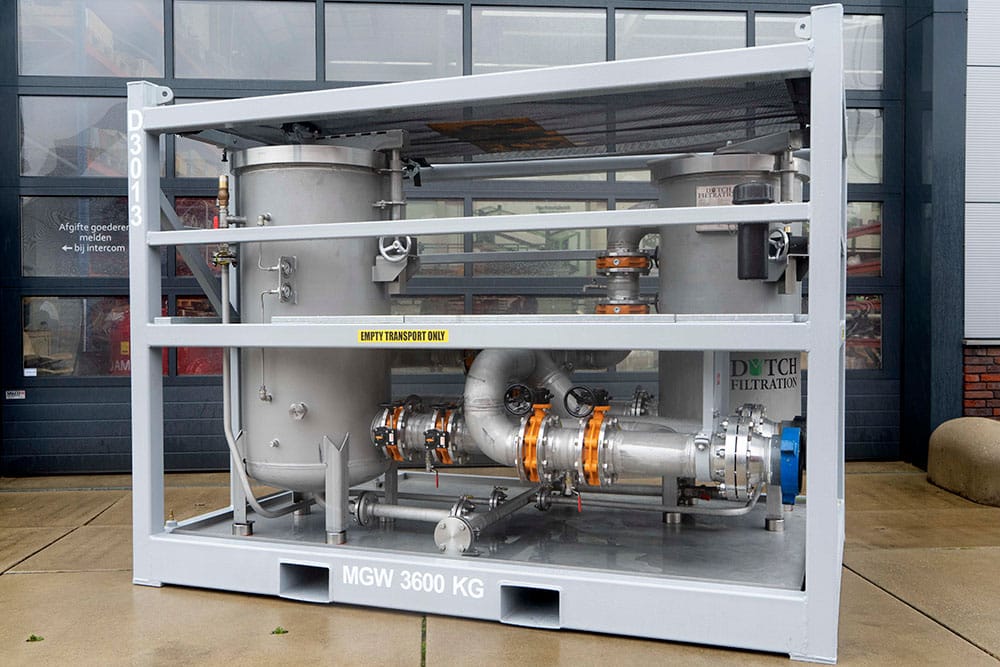

Dual Vessel Cartridge Unit

The Dual Vessel Cartridge Filter Unit is based on 25 years of experience in manufacturing oilfield equipment. All new features are based on customer feedback and combined in our unique twin vessel filter unit. HSE, efficiency and reliability are the key drivers for our product improvement and design. For the vessel closure your can choose the Rudi Quick Opening Closure. This allows the operator to open and close the filter vessel quickly and safely for changing the filter cartridges. The unit is designed and built in accordance with DNV 2.7/ ISO10855/ EN12079 and certified by DNV or Lloyds. Our standard DFC24 unit has two housings with each 50 cartridges and 6 valves for parallel, in series and by-pass operation.

The Dual Vessel Filter unit is also available as Dual Vessel Bag Filter Unit and Dual Vessel Combi Filter Unit.

Features

- Compact footprint

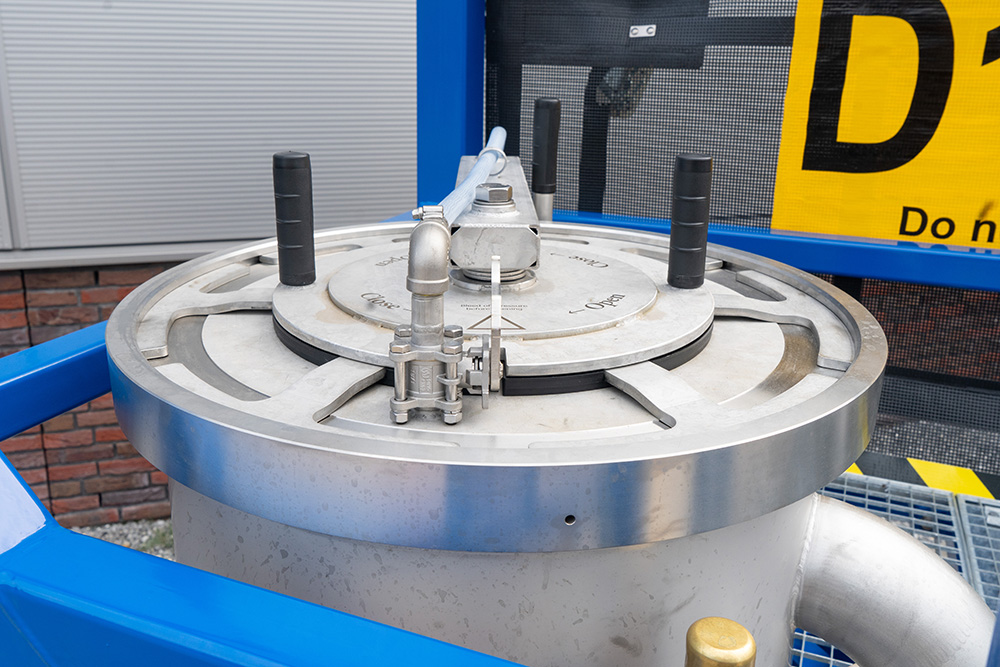

- Quick opening closure lid

- Simple Davit

- Frame designed and certified according DNV 2.7-1/ISO 10855/EN12079

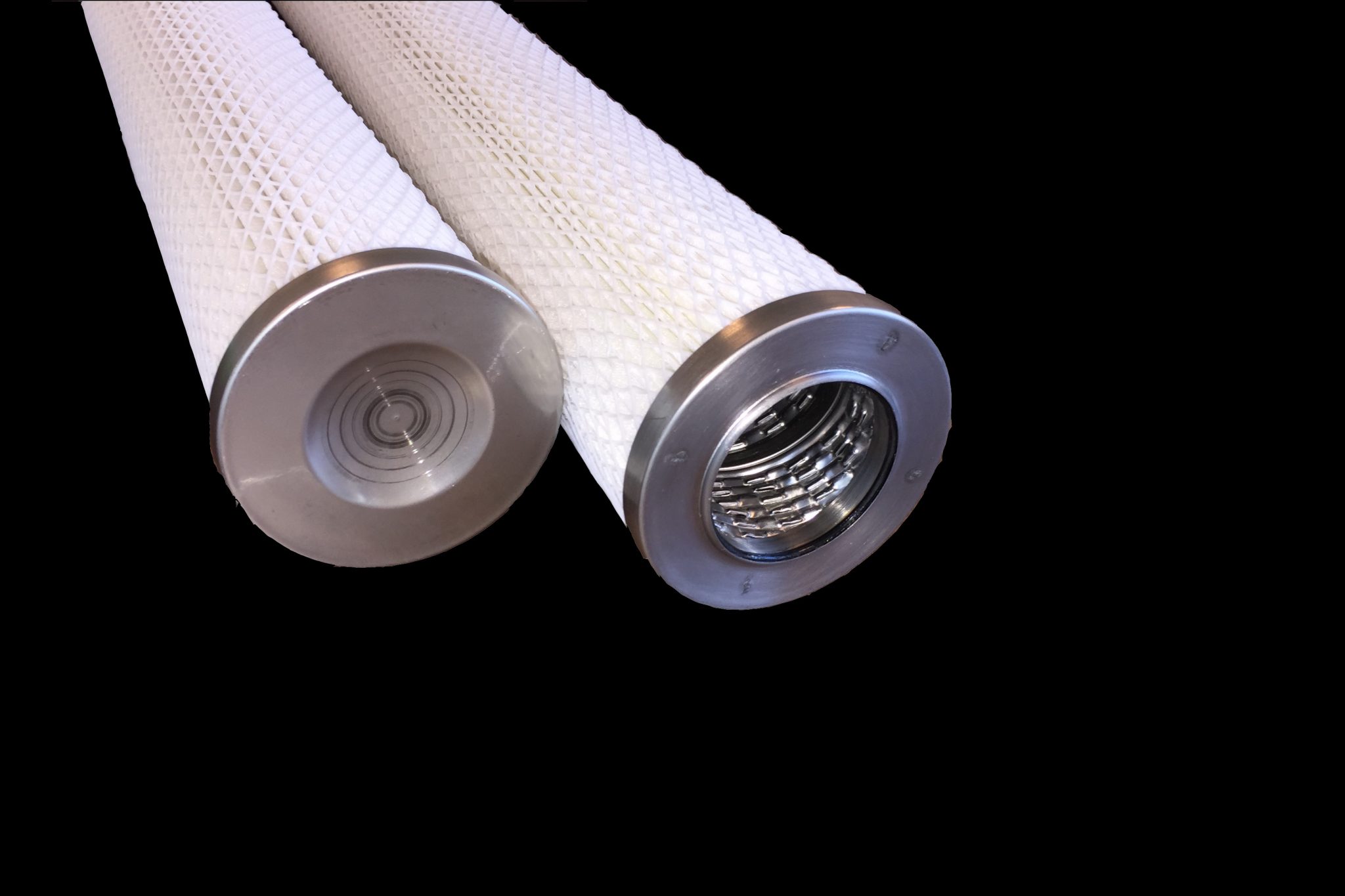

- All wetted parts SS316

- Connections unions fig. 206, 100% leakproof

- Standard 10 bar design to PED2014/68

- PED module A for hazardous fluids

-

Applications

- Completion fluids

- Produced water

- Work over fluids

- Gravel pack fluids

- Wellbore clean up fluids

- (Bio) diesel

- Surface water intake

- Process water

- Pre filtration RO

- Frac fluids

- Pipeline flushing

- Wastewater

-

Options

- Swing bolt closure / Rudi quick opening closure

- Pneumatic or Hydraulic closure

- Stainless steel drip pan

- Drain manifold line

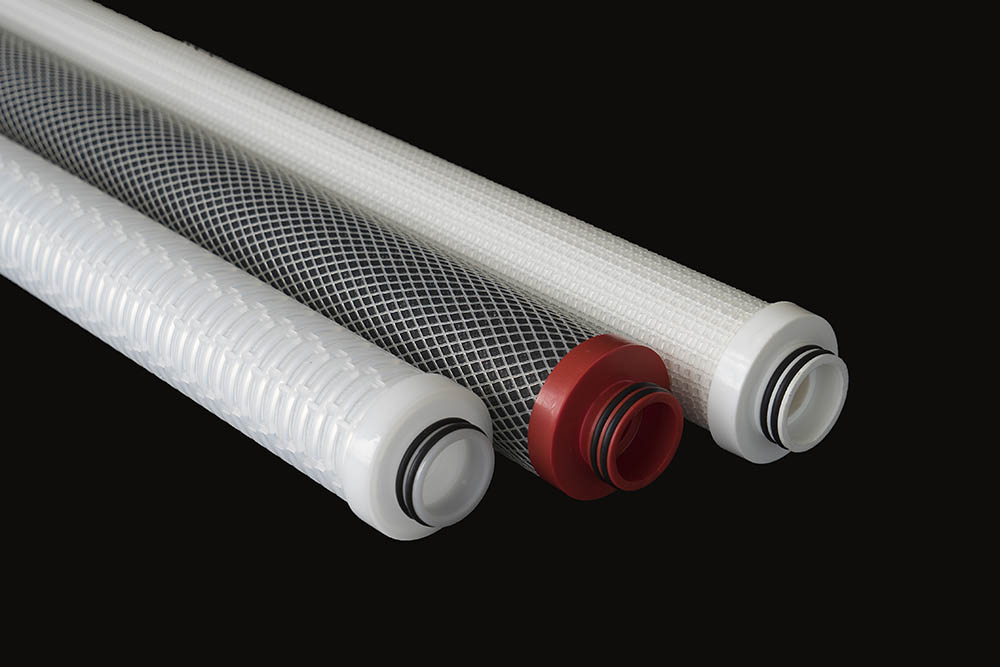

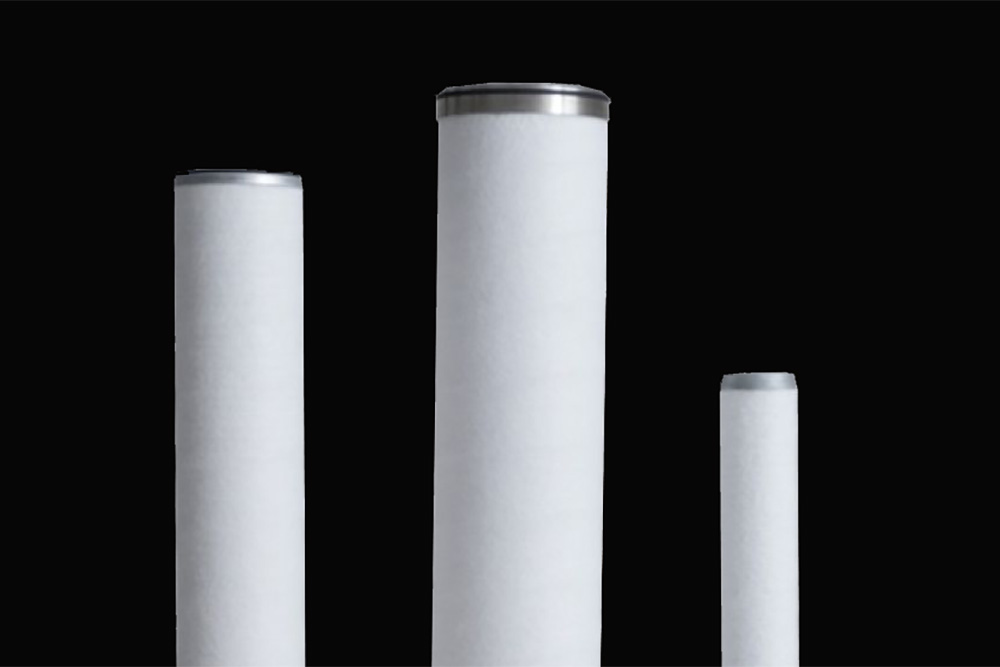

- 1-200 cartridges per vessel

- 6 inch High flow filter configuration, flow rate up to 1000 m3/hr (95 BPM)

- Carbon steel or Duplex Stainless Steel

- Manifold sizes and connection type

- Design pressure up to 6000 psi (400 bar)

- Vessel linings: rubber, epoxy, glass flake, PU

- ISO Corner Blocks

Unique design features

Inlet/outlet union fig. 206

Easy to open and close safety gate

Safety protection at top DNV 2.7-1 offshore lift frame. Heavy duty netting for easy and safe access to skid. Big improvement compare to old fashioned steel grid gates

Document box, 100% waterproof, easy to open and close

Dual filter unit that meets global demands

A Dutch Filtration dual vessel filter unit is built for a faster, safer and more ergonomic operation and contributes to efficiency, cost reduction and maximization of oil and gas production. With more than 45 years of experience in the oil and gas industry and over 25 year of experience in manufacturing oilfield equipment (Duplex filter TDW610, VPL, Filter Press) is Dutch Filtration a specialist in filter solutions that can handle any demanding situation. During those years the design of the dual vessel filter unit has been improved and optimized to the highest standards worldwide.

Dual vessel filter unit meets demands of customers worldwide

Dutch Filtration, designs, manufactures, builds, innovates and tests every dual vessel filter unit in-house. Our team listens to the needs and feedback of our customers. Their input directly improves the design of the next dual vessel unit. Over the years this process has helped us improve our equipment. Thus every dual vessel filter unit is built not only with decades of specialized knowledge, but also on the experience of hundreds of customers that need the best quality for their operation.

The unique design features of Dutch Filtrations dual vessel filter unit

As a consequence of the feedback of our customers every dual vessel filter unit made by Dutch Filtration has unique design features. Compared to the duplex filter units of other companies (a.o. TDW 610) we did several upgrades. Instead of the old fashioned swing-bolt system, the dual vessel filter unit is equipped with Rudi Quick opening closure. This enables much faster and safer exchange of filter elements. The old fashioned steel grid gates are replaced by heavy duty netting that provides easy and safe access to the skid.

Dual vessel filter unit meets highest standards

HSE, efficiency and reliability are the key drivers for the improvement of the Dutch Filtration dual vessel filter unit. This means that all our equipment, including the dual vessel filter unit, is certified as top DNV2.7-1/ISO 10855/EN12079 offshore.

Related products

Experience & Innovation

Do you have questions or do you want more information?